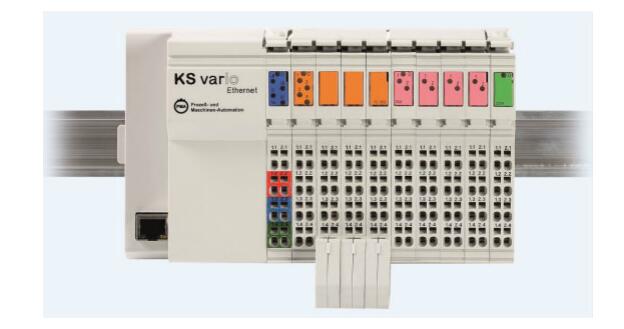

KS vario

High precision, energy saving, no overshoot stability control, expert PID self-tuning, group self-tuning, water cooling/air cooling/oil cooling special algorithm, soft start, fault output average function;

Modular design, compact structure, flexible expansion, input and output modules can be arbitrarily matched according to customer needs, avoid unnecessary waste, and reduce inventory types;

Standard guide rail fixed, plug and pull terminals, simple installation, configuration of 30 temperature control only a few minutes;

High system compatibility, support a variety of fieldbus protocols :Modbus RTU, ProfiNet, Profibus, Modbus TCP, Ethernet IP, CANopen, DeviceNet, etc.

It adopts the powerful and convenient engineering configuration software BlueControl, connects with KS vario through a separate RS232 interface, can easily configure and monitor the control system, and has the function of simulating the control mode and control loop.

High safety, including sensor disconnected input loop monitoring and output "hold", control loop monitoring (loop alarm), measurement correction, alarm and insurance functions, alarm output, heating current monitoring and alarm, heating current monitoring power supply voltage fluctuation compensation and other functions.

KS98-2 Multifunctional automation unit

PID master also has good control effect for high order process objects that ordinary PID cannot handle

I/O expansion is extremely rich, universal analog input, high resistance signal input (oxygen probe), digital input you name it

Up to 10 or so PID loops can be implemented on this unit, more if I/O is extended via CANopen module (KS800,KS816,RM200)

Fixed value control/program control/maximum/minimum/average/cumulative value/rate of change/cascade/override/timing/sequential/logical operation/formula/data logger... User availability

Build your own controller and use up to 1000 blocks at a time!

Multiple KS98 can exchange data with each other through CANopen